Success Stories

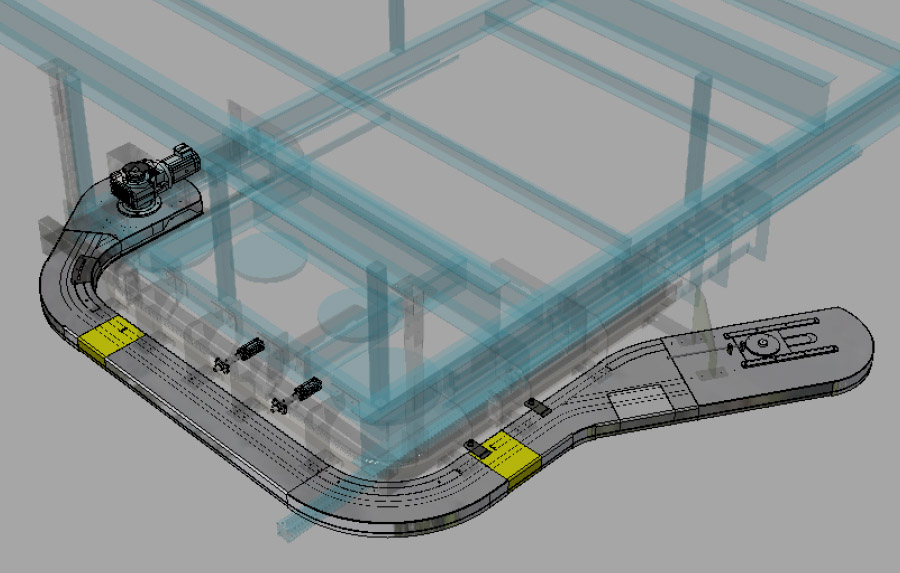

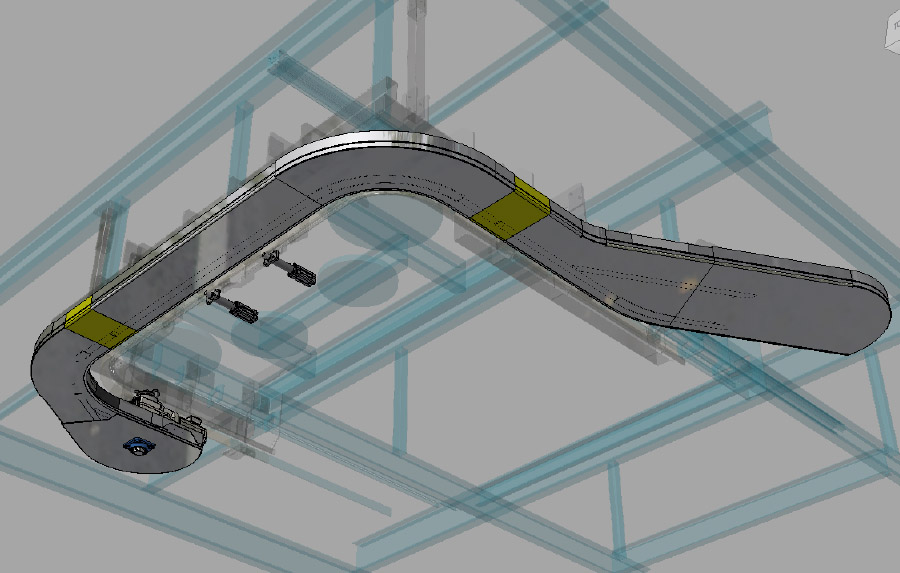

Beef Hide Puller – Indexing Shuttle Conveyor

Background

Primary Food Processors are continually seeking to reduce waste and adapt machinery to evolving food safety requirements.

Well-designed modifications to existing machinery can often provide a cost-effective solution to these requirements.

Brief

Our customer had an older beef conveyor in their hide pulling area. Over time, the works sped up their processing, and the old conveyor (at its faster speed) had carcass swing issues. This created issues around Health & Safety and productivity.

Solution

The Todd Engineering team designed with the customers electrician to design a shuttle conveyor which provided the following:

- Controlled speed while the carcass travels to the pulling position.

- Minimal carcass swing.

- Better positioning of carcass for hide pulling.

The new elevator and conveyor changes were installed with a 10mm ceiling support beam clearance – a perfect outcome for the existing space.

Results

The shuttle conveyor successfully minimised swing from the hide pulling process. This allowed the customer to continue to comply with health & safety regulations and increase productivity.

The customer is very pleased that the project objectives were achieved.

Phone:

03 456 4283

Hours:

7:30am - 5:00pm Monday to Friday

Address:

26 Orari Street,

South Dunedin, Otago