Success Stories

Automated Beef Quarter Sort and Marshalling Chiller

Silver Fern Farms Finegand

Background

Primary food processors are continually looking for ways to improve capacity, efficiency and safety within the existing footprint of their processing plants.

Brief

SFF Finegand is a multi-species processing site and the largest facility in the SFF network. This project was initiated to manage the increased growth in beef processing and meet market demands for premium branded beef through implementing an automated sortation and marshalling chiller for beef quarters prior to boning.

The project faced a number of challenges expected with brownfield development and time to deliver the project to market. This included converting existing disused factory footprint previously used for lamb, project design, project delivery timelines and being able to commission without any disruption to production.

Solution

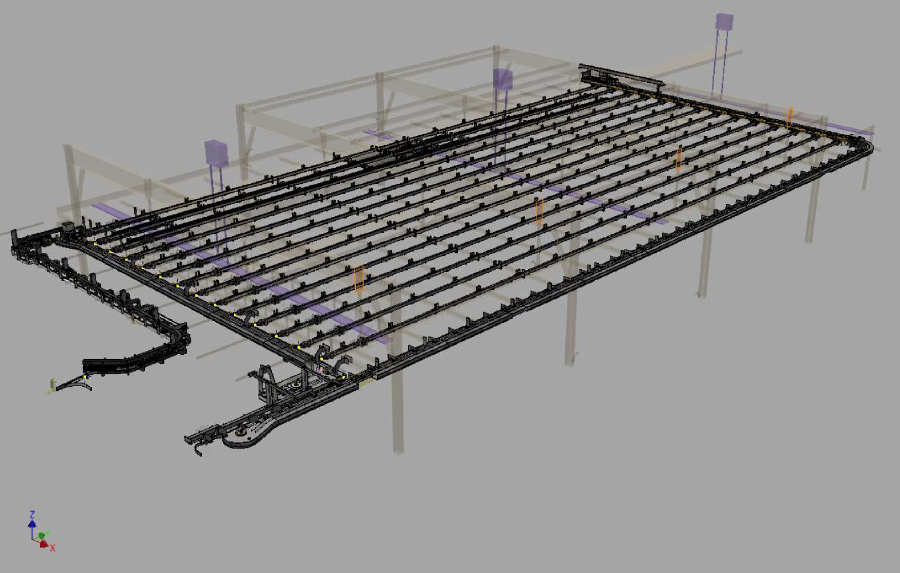

The team at Todd Engineering presented a design which included:

- Structural strengthening and modification of rails to handle the additional height and weight of the beef quarters.

- Installation of supply and trim conveyors to move the beef quarters in and out of the new chiller quickly and safely.

- A plan to install and commission 2 lanes as proof of concept, before installing the remaining 12 beef lanes.

The increased building loading required structural strengthening work, which commenced on approval of the design by the SFF team. The 2 automated beef lanes and conveyors were installed and commissioned within the agreed timeframe and both operated and ran perfectly.

This has paved the way for completion of the additional automated beef lanes.

The team at Todd Engineering were also able to modify a standard stacking attachment to make them more versatile and efficient, given the limited ceiling space in this type of application. An innovation able to be utilised in future projects.

Results

SFF Project Manager Stanley Burlison was very happy with the new automated chiller and the timely manner that the project was completed in.

Executing this project improved reliability of day to day operation of the beef business by providing greater control of the carcass cold chain from Slaughter to Boning. This has allowed the business to better handle the growth in beef throughput while the ability to sort and Marshall carcasses will allow for optimal value recovery of the branded programs and provides future options for further automation

The Todd Engineering Team was happy to assist SFF Finegand repurpose its existing space to increase capacity, making it more productive, profitable and safer for their team to work in. The labour requirement has also been reduced in an area that is, historically hard to man reliably.

Phone:

03 456 4283

Hours:

7:30am - 5:00pm Monday to Friday

Address:

26 Orari Street,

South Dunedin, Otago